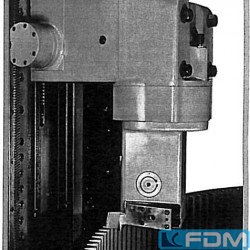

Gear Shaper

MAAG SH 250/300 S

- Stock number:

- 1007-6389

- Year / Condition:

- 1982 / used

- Control unit:

- conventional

- Country of origin:

- Switzerland

- Freight basis:

- ex Warehouse

- Item location:

- D-40721 Hilden NRW

- Delivery time:

- immediately

Picture / documents / videos

Technical specs

Details

- max. wheel diameter:

- 3080 mm

- min. wheel diameter:

- 200 mm

- module (generating cutter):

- 50

- module (profile cutter):

- 25

- max. number of teeth:

- 1000

- min. number of teeth:

- 12

- tool length - max.:

- ca. 312 mm

- min. ram stroke:

- 70 mm

- dividing plate diameter:

- 1116 mm

- table bore diameter:

- 420 mm

- table travel max.:

- 2 x 460 = 920 mm

- ram stroke speed:

- 3,2 - 40 m/min.

- max. ram stroke:

- 700 mm

- table load:

- 15000 kg

- Ram strokes per shifting:

- 8 - 150

- depth of hole:

- 1200 mm

- max. wheel diameter (internal cutting):

- 3300 mm

- max. dia. of teeth cutting (internal gearing):

- 2940 mm

- Distance between head and table:

- 1180 mm

- gear width (internal cutting):

- 365 mm

- clamping table diameter:

- 1100 mm

- helical adjustment of ram:

- unbeschränkt/unlimited °

- max.helical angle:

- 35 °

- dimensions of the machine ca.:

- 6550 x 4275 x 3310 mm

- power capacity:

- 71 kW

- weight of the machine ca.:

- 38000 kg

Accerories

- chip conveyor

- 1

- Local rim support (swivel head mounted)

- 1

- Local rim support (bed mounted)

- 1

- Internal gear cutting attachment JVS-250

- 1

- Work base plate Ø1800 mm

- 1

- Longitudinal Correction Device

Description

The machine is practically new and will be delivered with a precision chart. Cutting quality DIN 7!

The main characteristics of the machine are excellent accuracy and high versatility in producing external gears, internal gears,

herringbone gears, double helical gears and gear racks. The outstanding economy of the MAAG SH 250/300 S derives from the high

metal removal rate (for material until 1400 N/mm2 and 400 HB) and simplicity of form and long tool life of the roughing cutter, which

keeps the tooling costs extremely low. After the roughing operation, the gear teeth are finished machined in the same set-up by the

generating method. And that makes it in most of all cases possible, to avoid grinding. With the full swivel cutter ram, any desired

helix angle can be set. The finishing generating operation yields a very good tooth accuracy in short machining time. The machining

cycles for the plunge cut and the generating operations take place automatically. The vertical working range is so large that even

double-helical gears can usually be completely machined without altering the set-up. The cutter ram is driven by a DC reversible

motor via a 7-start spindle. Helical gears or double helical gears with a small run-out groove could be cut by a helical rack shaped cutter.

When using the swivelling cutter holder for cutting gears with great helix angles the ram stroke could be highly reduced.

Contact seller

Teco Werkzeugmaschinen GmbH & Co. KG

Westring 140721 Hilden Phone: +49(0)2103 3682 0Fax: 0049 2103 3682 20